CENTAMAX never ceases to amaze you

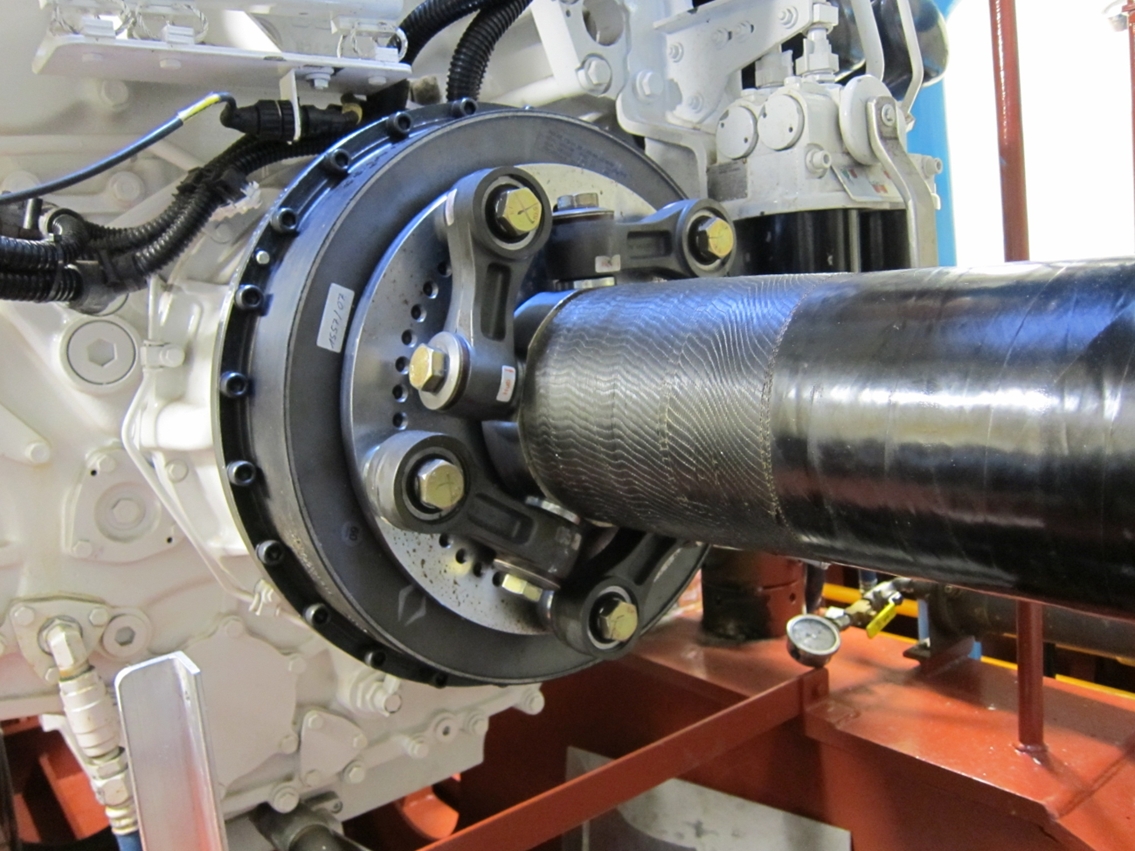

CENTAMAX couplings from CENTA Gmbh are used in an extensive number of applications such as trains, shipping, agricultural machinery, energy applications and others.

If after several years of hard work it does become necessary to order a new elastic element, there are a few parameters that are important.

Parameters to define an elastic element

One of the great advantages of the robust CENTAMAX elastic coupling is the great diversity of versions in which it is available. It is therefore important to specify the right parameters.

What is the build size ?

Example CENTAMAX 240 or 5000 or 6000 or 10000. This is marked in large on the elastical ement. The picture below shows a build size 240.

Caution: The patent numbers sometimes found on the CENTAMAX coupling are not useful for type identification.

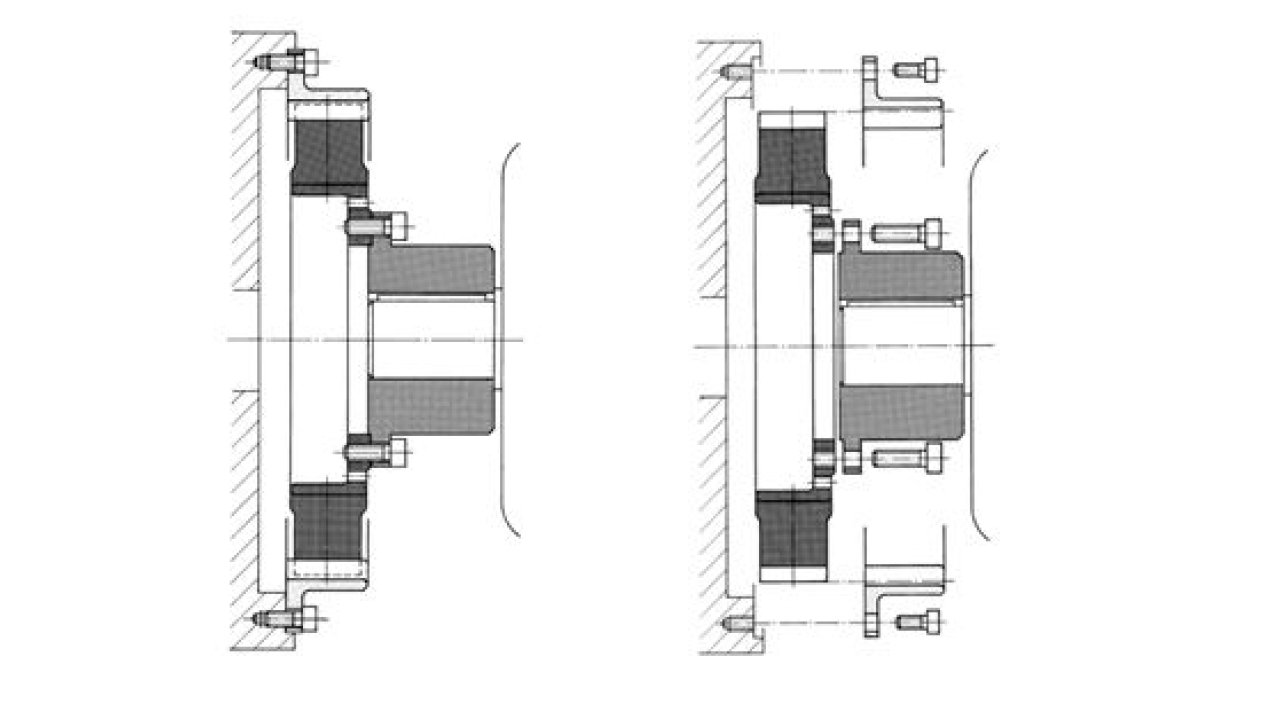

Execution

Besides the CENTAMAX S, we also have other versions such as the CENTAMAX HTC (with ventilation channels),CENTAMAX B (with pins) or CENTAMAX G (with a special flange).

What is the hardness of the elastic element ?

CENTAMAX can be supplied in various hardnesses such as 50, 60, 70, 75 shore A. This affects the elasticity and rigidity of the coupling and is therefore very important for the proper functioning of the entire installation. See for example 60 in a circle, as in the picture below.

Optionally, a colour code was also used on the teeth. (See checklist for colour codes)

If you do not see a marking on the elastic element, we can also measure the hardness with a hardness tester. This can be done on a sample , but also on site at your installation.

Material

CENTAMAX exists in NR (natural rubber/ black), SILICONE (yellow transparent colour) and new also CENTALAN. CENTALAN HT is a newly developed synthetic elastomer, which can replace the more expensive SILICONE elements in a wide range of applications. In addition, this new rubber compound has been specially developed to have the same dynamic properties as natural rubber. CENTALAN HT also performs better mechanically than the SILICONE alternative.

CENTALAN HT can therefore be used for applications where critical high temperatures may occur and, in addition to its good resistance to high temperatures, this new development also delivers increased resistance to UV radiation, ozone, oxygen as well as chemicals, steam and hot water. Because CENTALAN HT ages less quickly, a longer service life is possible. The mixture has good resistance to oil and fuel (i.e. similar to that of natural rubber). CENTALAN HT can be used for temperatures between – 25 °C and + 100 °C (short-term itself up to+ 120 °C). Typical applications are cogeneration plants and quasi continuously running sealed drives where higher temperatures can build up.

Is the element easy to disassemble ?

For elastic couplings mounted between a diesel engine and an alternator, it is important that the coupling element can be dismantled without dismantling the generator. An E-mount saves a lot of costs in this case. The sketch below shows how to dismantle and replace an E-element very easily.

If the fixing holes are drilled smooth, without threads, it is a standard element. Attention : there are also some threaded holes (to enable the disassembly of the element).

If all the holes are threaded, as in the picture below, then it is an E version, i.e. a demountable element.

Maybe you have a CENTA drawing number ?

We can certainly work on that. In fact, there are many combination possibilities with CENTAMAX. A Centa drawing number provides important information of the flange, type of elastic element and hub design (width, spline type, number of teeth, etc. ).

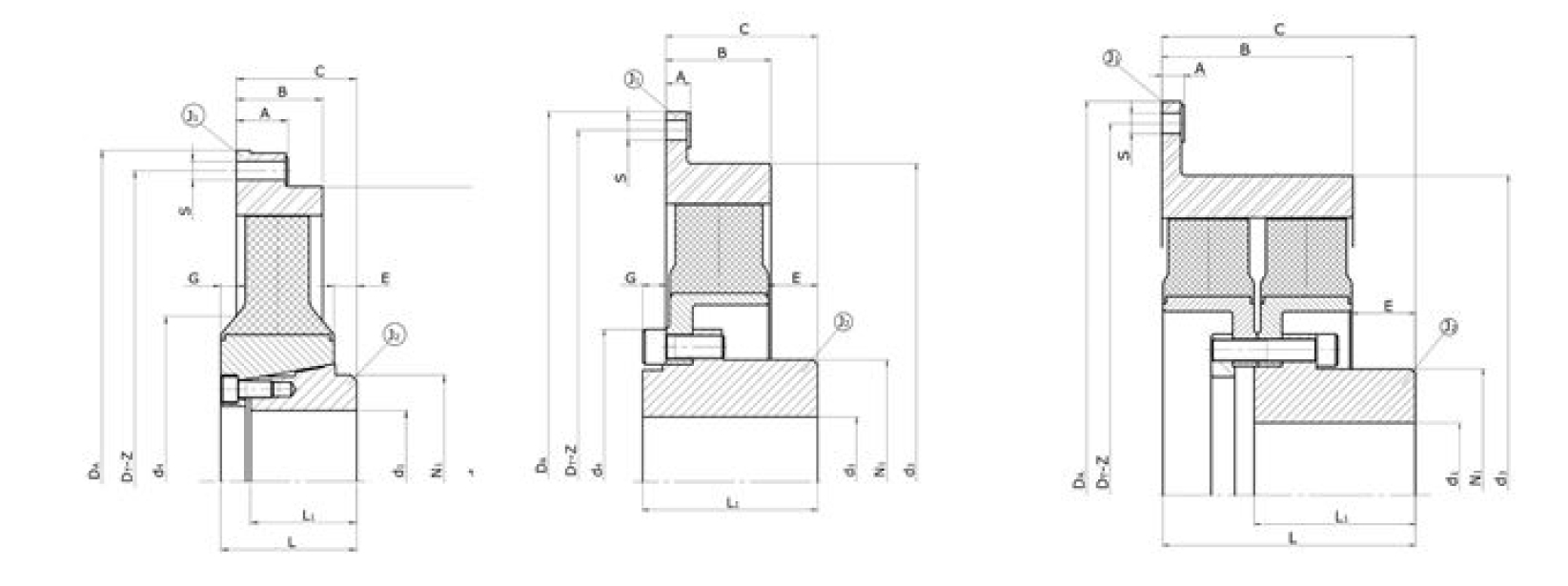

How is the coupling mounted ?

See on the below different mounting options. This translates into a code SCA, SCE, SCB, SCD etc. See the manual for this.

You can download the easy CENTAMAX checklist here.

Need technical advice from our specialist?

Suppliers & Brands

Downloads

Related Products

Couplings

Couplings from Centa

Rigid Steelflex Couplings from Falk by Rexnord Regal

Bellows couplings from Rexnord Regal

Slip clutches and chain clutches from Cross and Morse