Transport chains

Transport chains can be equipped with various accessories suitable for the nature of the load being transported.

Robust chains for your transportation

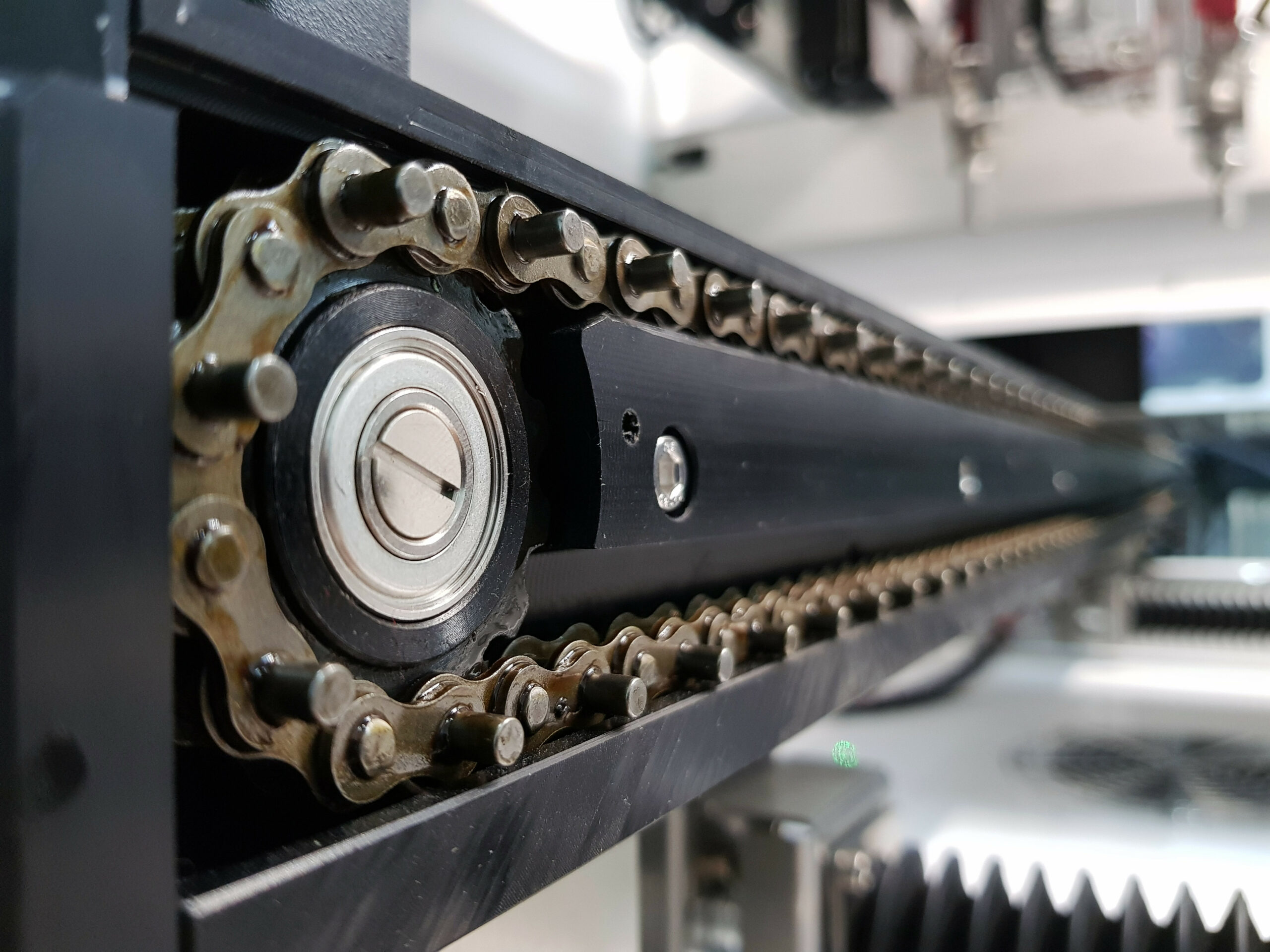

Conveyor chains consist of pins and bushings connected by plates. Their main distinguishing feature is that they can be equipped with various accessories suitable for the type of conveyor used and the nature of the load to be moved. Their pitch, which is usually considerable, is not unique but can be chosen from a wide range.

Products

ISO Standard conveyor chains

SEDIS conveyor chains comply with the ISO 1977 standard.

The pins of these chains are usually solid, but the standard allows them to be equipped with hollow pins so that accessories such as cross rods can be attached to them when two chains run parallel.

We have three possible basic chains, which can be equipped with options such as plates and carriers.

Bus chains (without roller) for low speeds (conveyors, feeders, scrapers, etc.) and in some specific cases where the chain accessories are load bearing and the chain becomes mainly a traction component.

Roller chains Example in elevator systems where the chain speed is higher and causes shocks in the sprocket transmission. The rollers, made of hardened steel or steel with a different treatment, protect the bushings and thus prevent tooth wear.

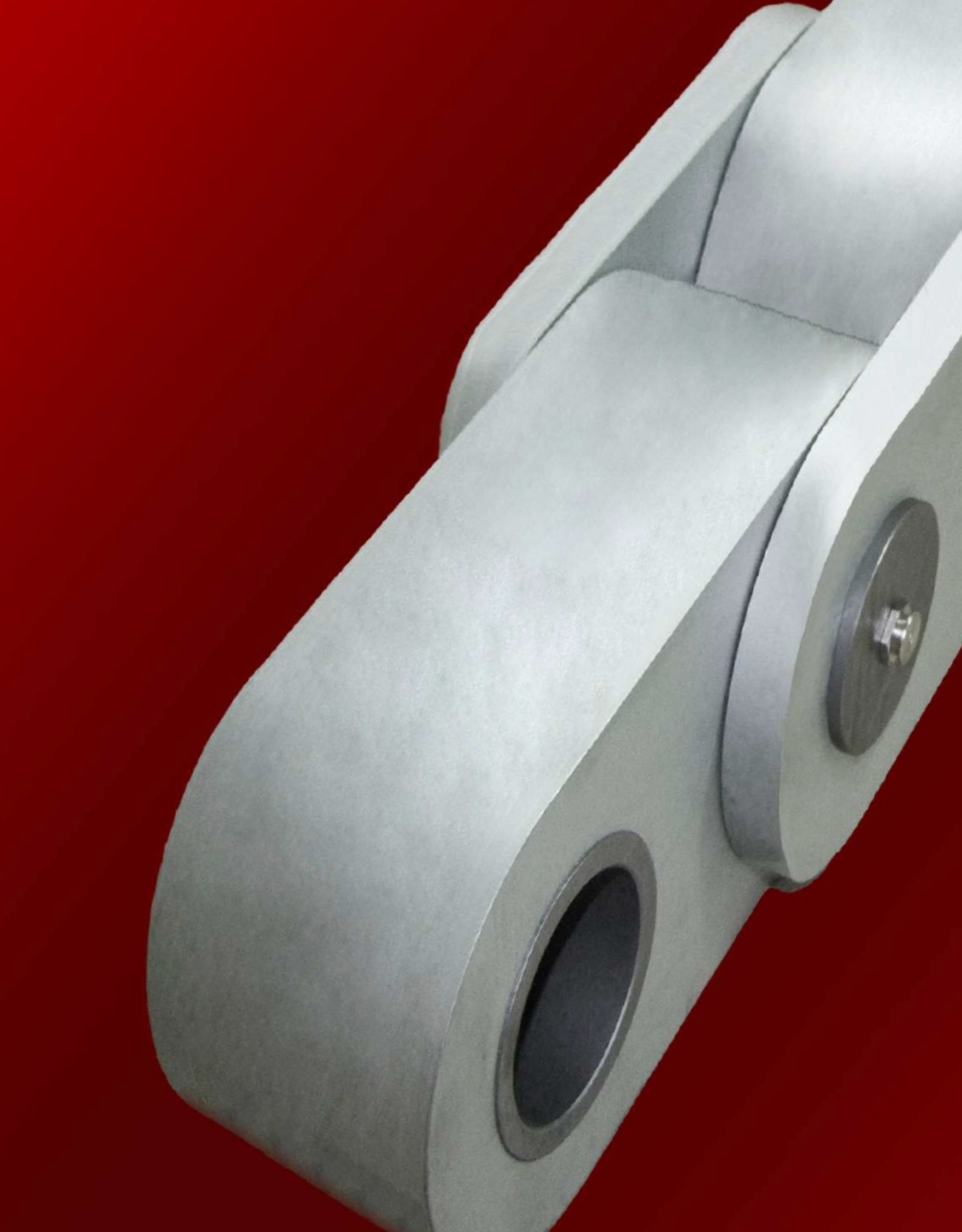

Wheel-chains (with rollers with a diameter larger than the height of the plates). They ensure that the chain runs on level ground. Wheels can be straight or flanged for lateral guidance. Straight wheels or wheels with flanges are made of treated steel.

Chains for load carriers and fasteners

In addition to hollow pins, there are many options for supporting or securing the loads carried, either directly or with accessories:

- Drilled plates with one, two or three holes for mounting plates or spacer bars. If these rods cross the chain, clearance must be provided on the sprocket teeth.

- Side plates with deep links that allow loads to rest directly on the chain rolling on straight wheels. These chains are usually used in parallel to form a bearing surface and spread the loads.

- Pleated attachment plates or in the form of brackets welded or riveted:

- G fasteners with or without holes forming a fixing plane parallel to the plates.

- F fasteners forming a fixing plane perpendicular to the plates.

- K-fixing plates with one or more holes forming a fixing plane perpendicular to the plates, with a choice of three values for the center distance (K2 with short, medium and long center distance), thus varying the width of the fixing plates. These fixing plates can be mounted on the inner plates, the outer plates, on one or both sides, according to a frequency to be specified.

BS Standard conveyor chains

We can also produce chains to British Standard (BS 4116) in terms of tensile strength and dimensions. Each chain can be customized with drilled plates, deep side plates, K-type attachment plates, scraper attachment plates, hollow pins, etc …

Transport chains French series

Block chains have high tensile strength at a limited width. They are used for transporting heavy loads, abrasive loads or when severe impacts are expected.

Galle chains

Galle chains are used for transmission at low speeds (tensile banks) or for oscillating motions (freight elevators, lock gates). Galle chains can transmit forces ranging from a few hundred newtons to more than 1,000 kilograms of newtons; on the other hand, the speed should not exceed 20 m/min.

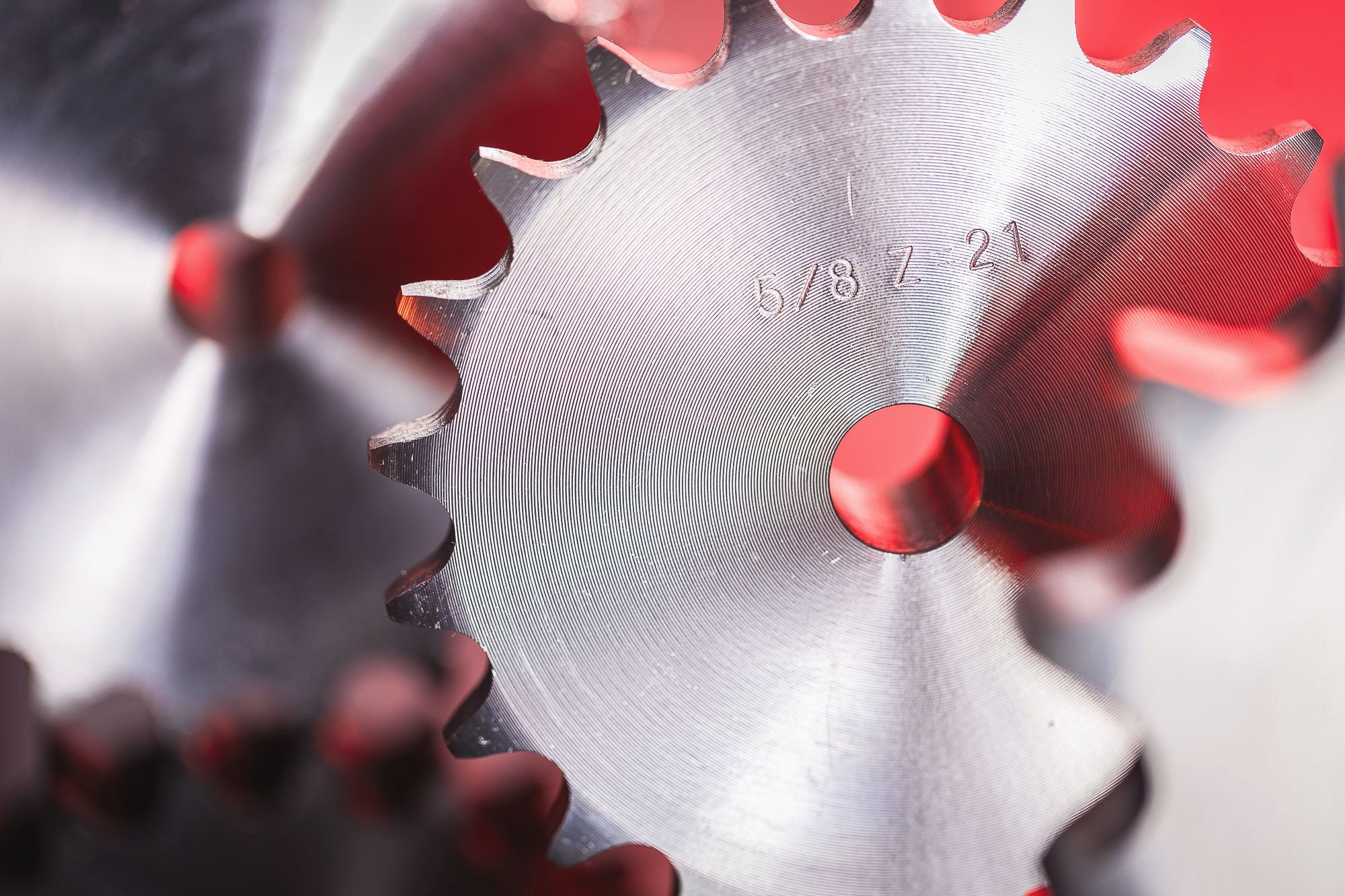

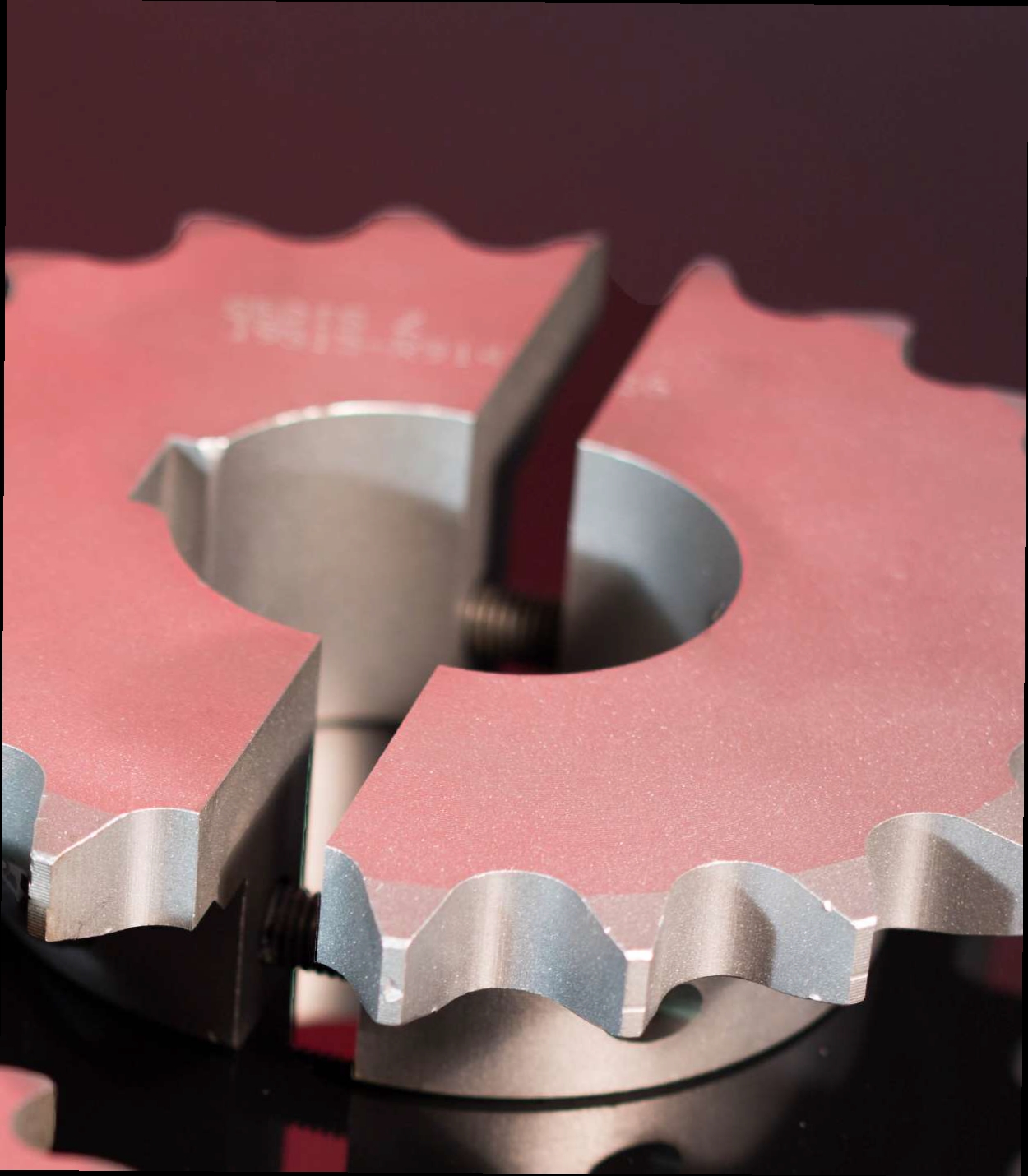

Sprockets

The sprockets used in conveyor chains are either made of machine-welded steel or cast iron. The teeth are usually unmachined cast or flamed, but they can be supplied to order with machined teeth (necessary when using bus chains).

We like to share our thoughts with you

To help you find the ideal chain for your installation and application, we would like to ask you a few questions to better understand your needs. Contact our experienced experts to work together to find the ideal solution for your issue.

Looking for technical support from our specialist?

Suppliers & Brands

Download SEDIS Coneyor Chains wheels sprocket

Reltated Products

Standard roller chain

Custom roller chain for transportation

Lift chains