Megadyne XMD: the timing belt for food-safe production processes

Well-known timing belt manufacturer Megadyne is launching a revolutionary timing belt with the XMD for use in the food industry. The Megadyne XMD timing belt is made of material detectable by X-ray ( x-ray) detectors and metal detectors, which can minimise the risk of food contamination.

The timing belt that prevents contamination in the food industry

In the food industry, breakdown or wear and tear of conveyor belts is a major risk. Unlike in other industries, such an occurrence within the food industry results in contamination of food and therefore a risk to food safety. It is therefore not for nothing that extremely high standards are maintained within the food industry to ensure food safety and hygiene of production and packaging lines. To minimise such risks, Megadyne has now launched the XMD timing belt.

The essential benefits of Megadyne XMD

Working with Megadyne XMD timing belts offers a number of important benefits for food producers and their customers. Firstly, XMD is an important step towards increasing food safety for consumers, which is endorsed by the fact that XMD is fully compliant with ISO 22000 and HACCP guidelines. By extension, XMD helps protect your brand’s reputation by preventing contamination. For example, manufacturers using XMD timing belts help the food industry by preventing large-scale recalls.

How does Megadyne XMD work?

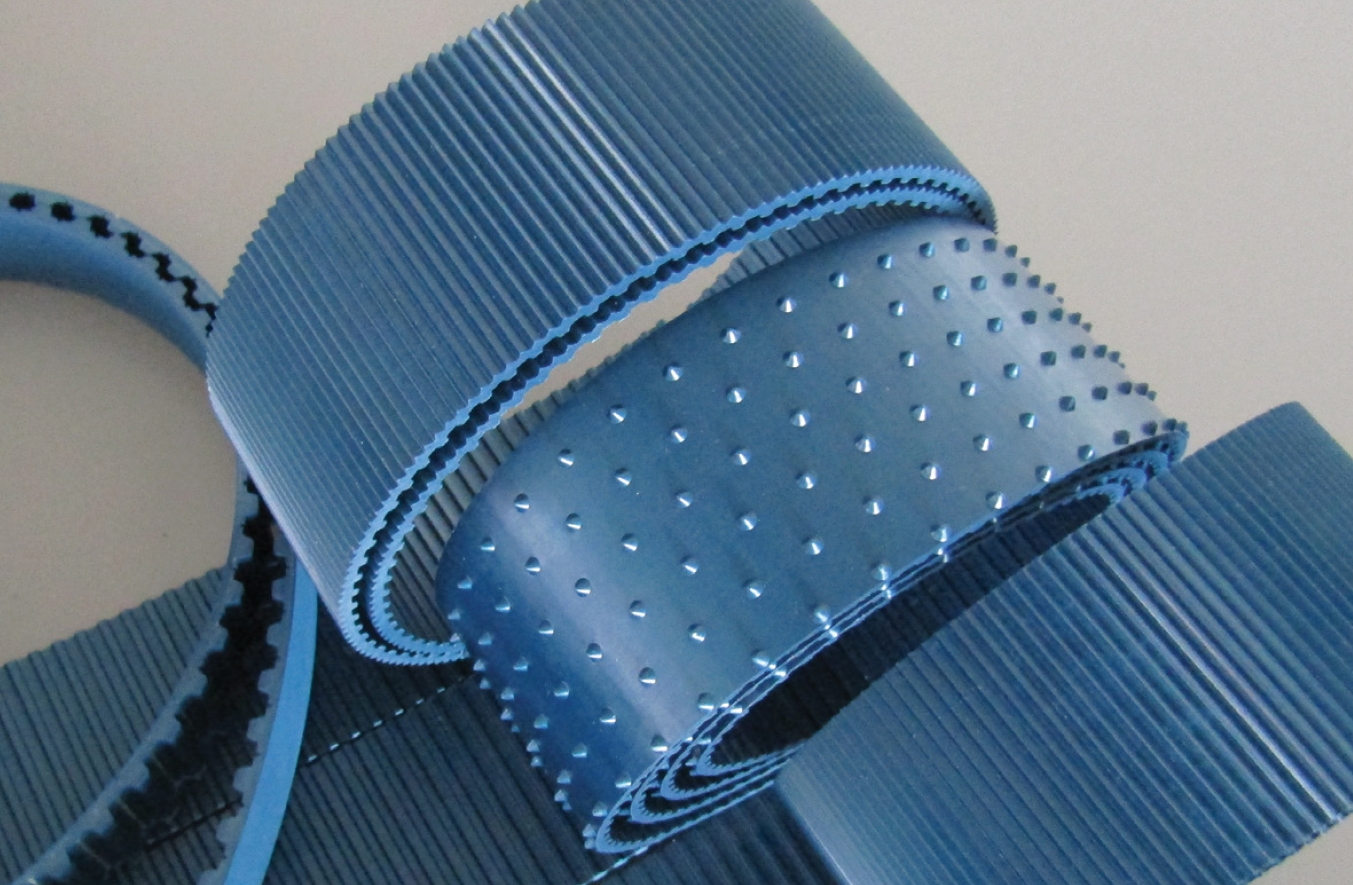

XMD timing belts contain a special PU (polyurethane) compound that is detectable by X-ray and metal detectors. Thus, all fragments of these timing belts that come into contact with foodstuffs (open end, welded and endless) manufactured with this compound are detectable. Besides these important food safety features, the XMD series also has other special hygienic design features, such as sealed edges and the use of blue as a contrast colour.

Test cards for extra security

As part of the revolutionary XMD series for use in the food industry, Megadyne has developed special test cards containing pieces of detectable polyurethane in different sizes.

These test cards can be used to demonstrate the effective performance of detection systems and also test the minimum detectable size of fragments.

Range and specs

The Megadyne XMD range consists of the Megalinear XMD and Megaflex XMD. The timing belts are available in all standard tooth profiles and lengths already in use for Megalinear FC, Megalinear FCM and Megaflex FCM.

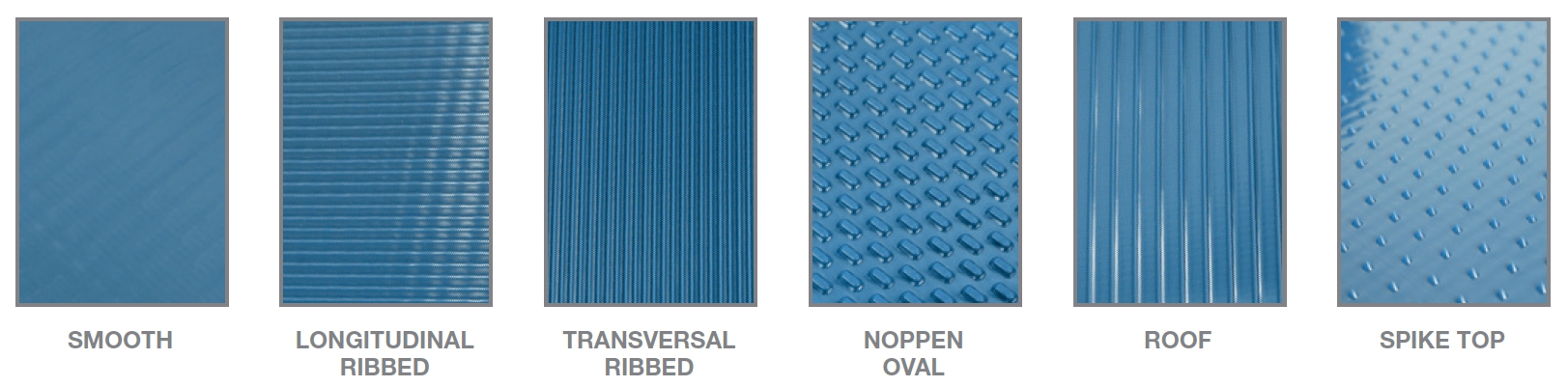

In addition to the standard flat surface, XMD can also be produced with various structures such as longitudinal ribs, transverse ribs, studs, pins etc..

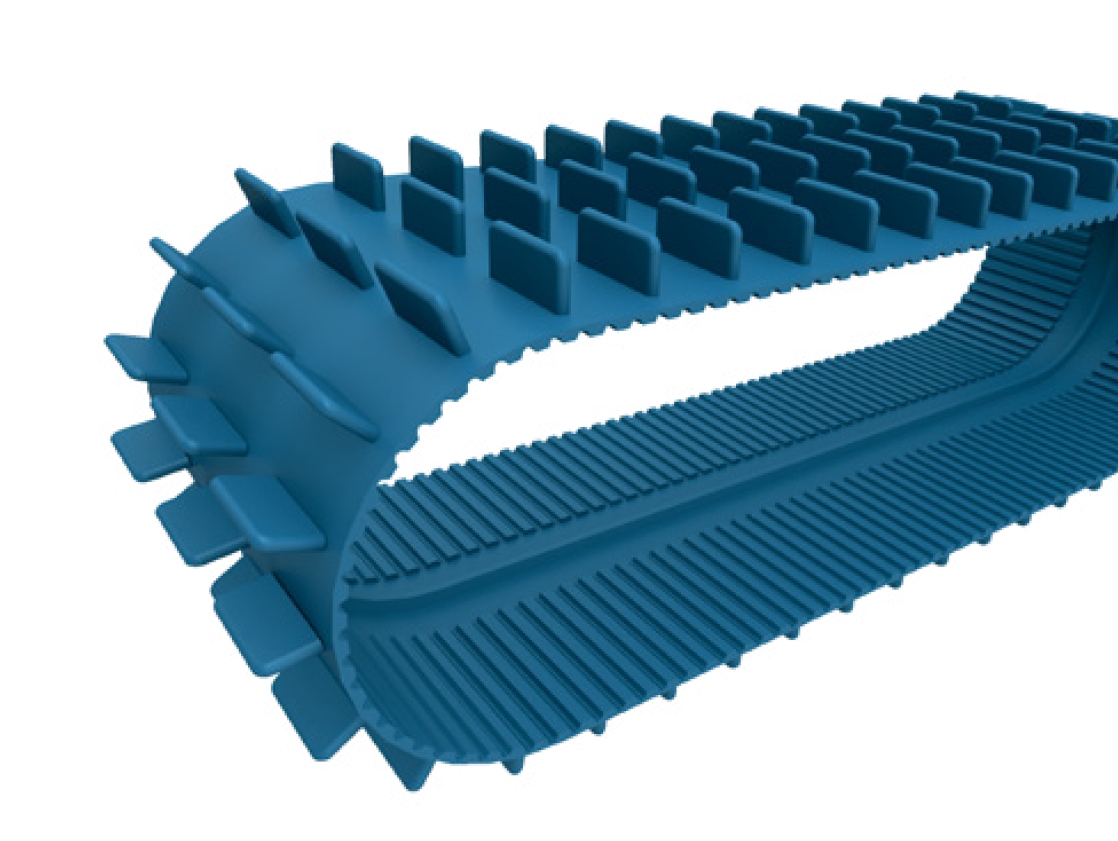

XMD can also be produced with carriers ( see picture).

Want to know more about Megadyne XMD for your business?

Our specialists will be happy to assist you if you are looking for specific conveyor solutions for your food-related issues. Please contact us so that we can share our knowledge and insights with you.

Need technical advice from our expert?

Suppliers & Brands

Download here the XMD brochure.

Related Products

Timing belt transmissions

Conveyors

Conveying by timing belt

Vacuum belts

Modular belts